Gadget

The gadget project is the first project we have to do for this minor. We have a 5-week period to come up with a feasible plug and play product. It also provides an opportunity for an introduction to 3D printing in terms of available possibilities and experience with a 3D printer and its software for those who are new in 3d printing .

The 5 weeks period of working in this project, exposes us to some risks. We divide these expected risks into two groups personal risks and technical risks. Personal risk may occur when, 1 or more person fall sick or are absent, and when there are delays in implementation. Technical risks may include cases in which, the 3D-printer is NOT working or a delay in manufacturing due to overbooked printers etc..

Research & Brainstorm

Let’s create some concepts! With all the knowledge we have gotten with our market research and by Ivanca linders the Concepting & Creativity lecture, we were ready to start brainstorming about concepts. During the brainstorm session, we all sketched our visual ideas on the gadget and come up whit 5 concepts. That ended up in a winner; the cup holder or so call grip – o – matic.

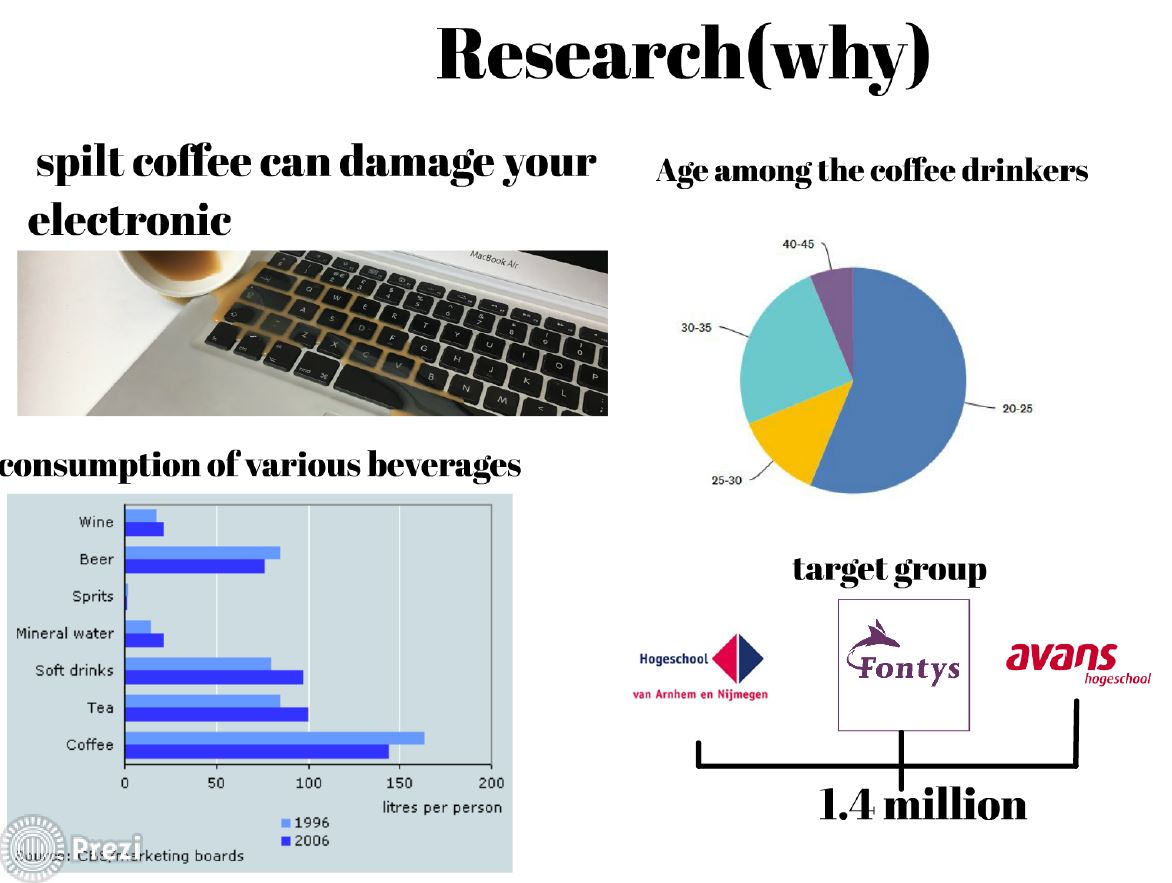

Target group

To ensure the success of our product on the market, a market research is needed to determine our target group. It is determined, that the target group are people who consumes hot beverages. It is established that hot beverages are significantly consumed – the consumers of hot beverages are our target group.

Sketching & CAD Design

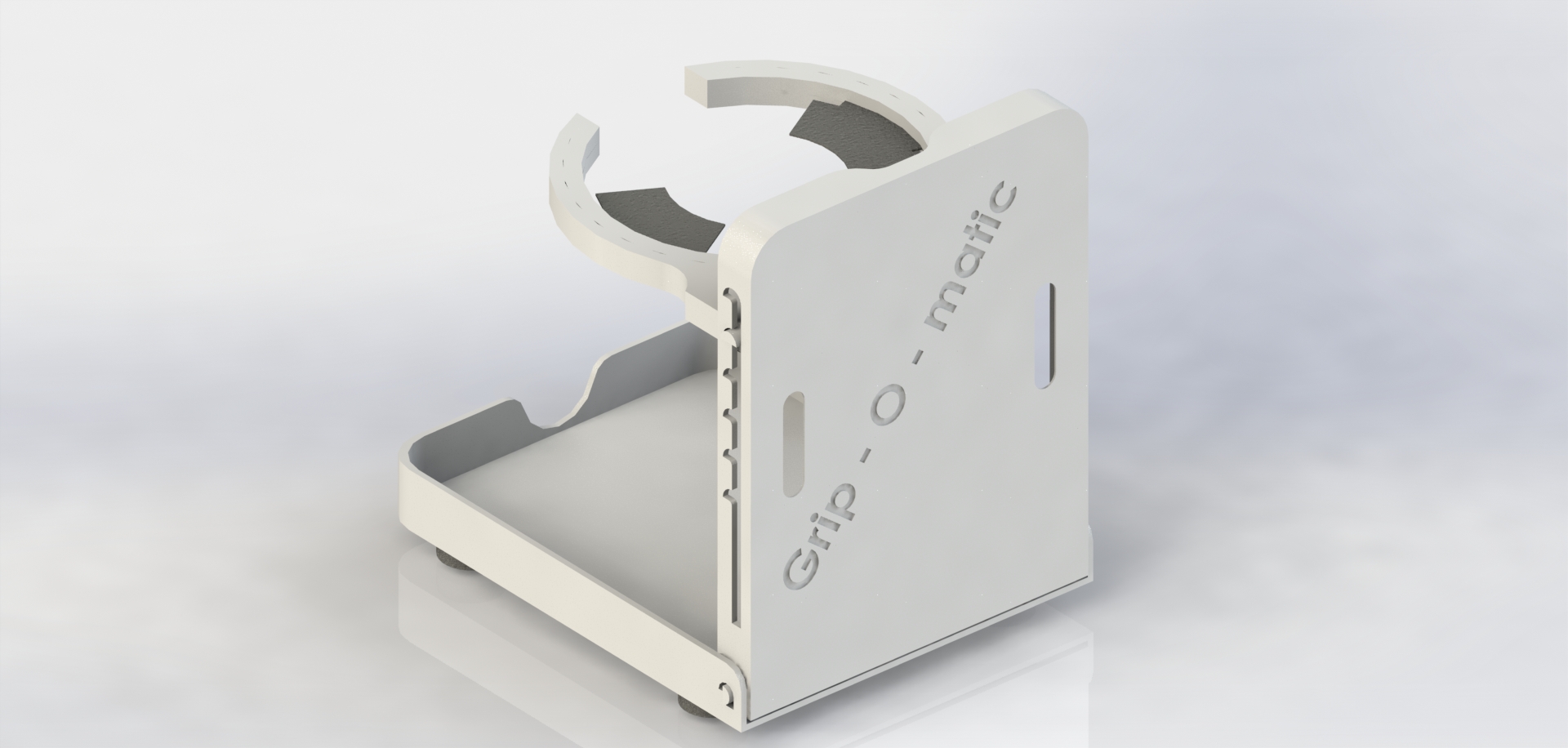

During developing possible solutions process as you can see we came up with a number of solutions for the cupholder. We combined several ideas to get the best solution. The winning idea was ,a foldable, easy to grab, lightweight cup holder which could comfortably fit in a back pack. In addition, the cup holder was adjustable for easy use with 3 different sizes. Next, we started with sketches of the first prototype.

After finishing with sketches. we wanted to see how it going to look as final proof of concept, therefore we used SOLIDWORKS 3D CAD software to make a representative design of our final idea.

Testing & Final product

For the testing part of our product we tried different scenarios. Grip - O - Matic was tested with different cups with different height and width. That allowed us to determine if the product is could hold different types of cups.

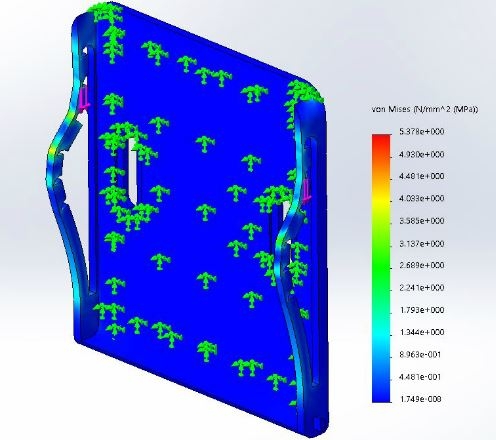

We also test the strength of the material and the shape used in this product SolidWork software, details are illustrated next to text.To see how much force this product can handle and to look if there is weakness appears in the shape of the product.

Presentation

The mini-symposium was on the 4th of october. Here we presented our product for the students and tutors.We have become 3rd of the 8 groups The location was at seats to meet einhoven.

presentation link

Click here for the prezi presentation.

Grip-O-matic